Dried Concentrates (Moisture-Absorbing Masterbatch Granules)

As the name suggests, dried concentrates are advanced functional materials developed to solve moisture-related issues. A desiccant is a substance designed to eliminate moisture and enhance extrusion and injection molding processes. It provides a complete solution for processors to reduce or remove unwanted moisture.

Moisture can be found in raw materials such as hygroscopic polymers, fillers, and pigments. These concentrates are used to remove moisture from raw and recycled materials such as HM, LDPE, LLDPE, and PP.

Dried concentrates are suitable for blown film extrusion, injection molding, and blow molding processes. They are directly used by homogeneously mixing the concentrates with moist plastic materials.

Moisture-absorbing masterbatch granules are available in pellet form, with a high concentration of active agents and excellent dispersion in the final product. The benefits of using this product include preventing processing issues such as coating bubbles, holes, and cracks.

Why Use Dried Concentrates?

Dried concentrates address issues caused by moisture during plastic processing and prevent moisture absorption during transportation.

Moisture can exist in raw materials like hygroscopic polymers, fillers, and pigments. Reprocessed polymers may also contain high moisture levels, which can lead to porosity, gaps, reduced tensile strength in final materials, or defects in extruded/blown sheets. In film applications, high moisture levels can cause film bubbles to burst.

How Do Dried Concentrates Work?

Dried concentrates chemically bond with moisture during processing, allowing higher levels of reprocessed polymers and fillers.

They help to reduce:

Coating bubbles

Gaps in films

Silver streaks in molding processes

Advantages of Dried Concentrates:

Increases filler addition levels

Maintains durability

Resolves moisture-related defects: bubbles, holes, streaks, and surface imperfections

Enhances mechanical properties

Eliminates moisture issues caused by additives/pigments

Reduces metal corrosion in extrusion machines

Eliminates the need for drying hygroscopic polymers

Zero energy consumption

No investment in drying machines

No factory space required

High moisture absorption capacity

Instantly solves moisture issues without production stoppage

Eliminates the need to dry waste before reuse

Applications of Dried Concentrates (Moisture-Absorbing Masterbatch Granules):

Plastic bags

Agricultural plastic films

Plastic-like paper products

Garbage bags

Recycled polymer processing

Cylinders and barrels

Woven bag processing

Injection molding

Double-wall sheets

Thermoformed sheets

Corrugated pipes

Why Choose Dried Concentrates from Pure Polymers?

Pure Polymers’ dried concentrates are highly recommended as additives, not only for converting recycled polymers (especially post-consumer materials) but also for raw polymers (due to storage issues or hygroscopic properties) that require costly and slow drying processes.

These concentrates chemically react with water molecules during plastic processing, effectively removing them. They are particularly useful for products made with hygroscopic materials where moisture-related defects (e.g., coating bubbles) are common.

Recommended Dosage:

Average dosage: 1-3%.

Storage & Usage:

Highly moisture-absorbent

Use within 16–24 hours after opening

Keep the original packaging sealed

Pre-drying may be required

Avoid excessive heat

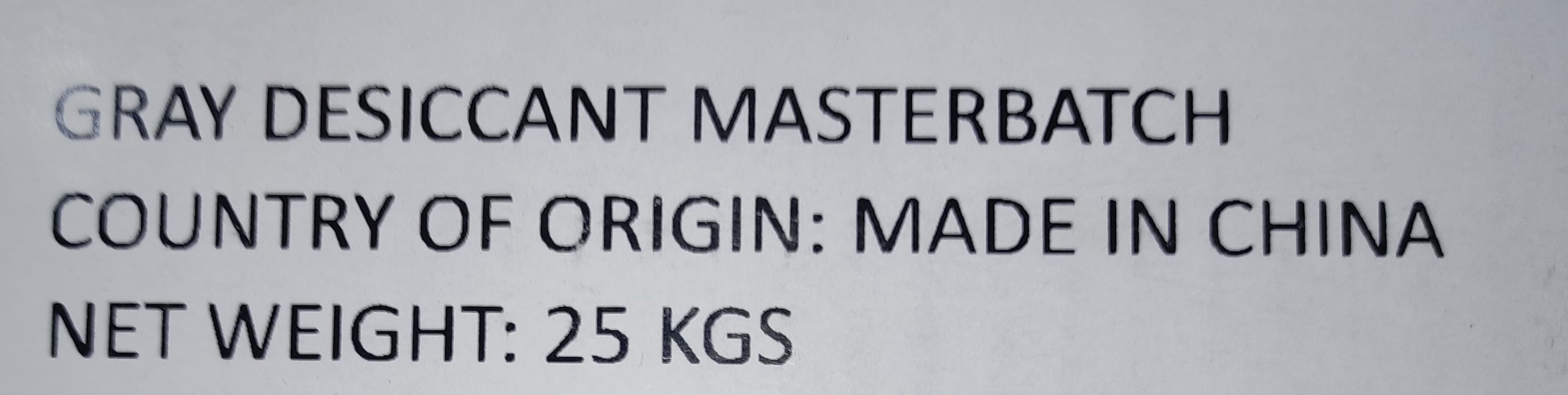

Packaging: 5 kg bags

Special Features:

Increases plastic value

Prevents or reduces moisture

Improves quality

Cost-effective and economical

Environmentally friendly and non-toxic

Dried Concentrates for Polyethylene (DES01)

Removes moisture from HDPE, LLDPE, LDPE, and starch-based bio-materials.

Replaces drying equipment, reducing energy and production costs

Mixed with HDPE, LLDPE, LDPE granules

Prevents weight loss from polymer drying

Non-toxic and eco-friendly

Product Description:

Recycled polyethylene and polypropylene often contain residual moisture. If not removed, this moisture can cause bubbles or leakage marks in finished products.

Moisture-absorbing plastic masterbatch is a new type of masterbatch specifically designed to remove moisture from polyethylene and polypropylene recycling processes. It simplifies drying, making it easy to use while improving production efficiency and reducing energy consumption.

Applications:

Widely used in recycled PE and PP materials

Suitable for plastic molding, injection, and film blowing

Shelf Life:

8 to 84 hours when exposed to air

6 to 12 months when well-packed

Use quickly for best results

If the granules turn completely white, do not use them

Handling & Storage:

Store in a dry, well-ventilated place away from sunlight and rain

Handle gently to prevent damage

Use appropriate transportation and storage methods

Additional Information:

Works like color masterbatch

Do not heat during mixing

Safe, non-toxic, and SGS-compliant

المراجعات

لا توجد مراجعات بعد.